Every drop of whisky might one day grow a field of wheat.

That’s not a metaphor. Behind a quiet revolution at the Indian Institute of Technology Bombay, researchers have uncovered a way to convert the toxic, foul-smelling wastewater from distilleries into a valuable fertiliser, potash. Their method is not just sustainable, it’s ingenious, using tartaric acid, a naturally occurring compound in grapes and bananas, to extract and recycle potassium from waste.

At a time when the world is teetering on the edge of a food and fertiliser crisis, this breakthrough offers a glimmer of hope. The solution is not buried deep underground, but hidden in our waste.

Why potash matters more than ever

Potassium, often supplied in the form of potash, is one of the three core nutrients essential for plant growth, alongside nitrogen and phosphorus. While its role in boosting crop yield is well understood, fewer people realise how fragile its supply chain is.

Globally, more than 95 percent of potassium-based chemicals are used as fertilisers. However, the majority of this potash comes from mining operations in just a handful of countries. The ongoing war in Ukraine and global trade disruptions have exposed just how vulnerable this system is.

According to the Food and Agriculture Organization (FAO), potash prices surged by more than 200 percent between 2021 and 2022, fuelling a wider food inflation crisis. Poorer nations with less access to fertilisers have borne the brunt. Farmers in South Asia, Africa and parts of Latin America are struggling to maintain yields amid shrinking supplies.

We need to stop thinking of waste as something to discard. It can be a resource, a lifeline. In this case, it’s a way to support our food systems while cutting industrial pollution.

-Dr. Inderjeet Khatri

The hidden cost of India’s booming distilleries

India is among the world’s largest producers of molasses-based alcohol. But the downside is the massive volumes of biomethanated distillery spent wash (BMSW) generated as a byproduct. For every litre of alcohol produced, about 8–15 litres of this nutrient-rich yet highly polluting liquid are discharged.

Left untreated, BMSW can wreak havoc on soil and water bodies. It contains high levels of potassium, organic matter, and dark pigments from caramelised sugars. In areas where this waste is used for irrigation, soil toxicity and heavy metal accumulation have been reported.

Traditional treatment methods often fall short, especially in dealing with the potassium content. While BMSW is rich in nutrients, its direct application to soil is problematic due to the presence of harmful compounds like melanoidins and phenolics. Moreover, excess potassium in water bodies can lead to eutrophication, harming aquatic life.

An elegant chemical twist: Tartaric acid to the rescue

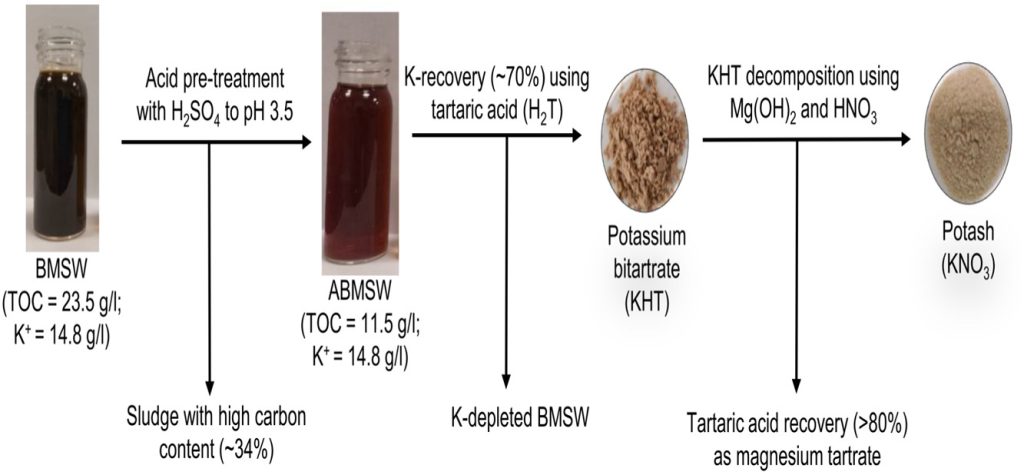

The research presented by the Indian Institute of Technology Bombay team hinges on a simple but elegant chemistry trick. They used tartaric acid, a weak organic acid, as a recyclable precipitant. When added to potassium-rich wastewater, tartaric acid reacts with potassium ions to form potassium bitartrate (KHT), a crystalline salt that can be filtered out.

This method achieved more than 70 percent potassium recovery from both synthetic wastewater and real BMSW samples. The process works optimally at a pH of 3.5, which favours the formation of HT⁻ ions (bitartrate) that bind selectively to potassium.

Notably, tartaric acid stands out from other chemical extractants like EDTA or DTPA due to its low environmental footprint and ease of regeneration. Where synthetic chelators persist in the environment, tartaric acid is biodegradable and naturally occurring.

Even more impressively, the team managed to regenerate the tartaric acid after use. By treating the recovered KHT with magnesium hydroxide (Mg(OH)2) and nitric acid, they produced potassium nitrate (KNO3), a premium-grade fertiliser, and recovered the tartaric acid as magnesium tartrate (MgT) for reuse.

A clean-up operation with multiple benefits

This dual recovery process is not just efficient, it’s remarkably clean. The researchers reported a 62 percent colour removal from the BMSW alongside potassium recovery. That means we are extracting fertiliser and detoxifying a notoriously difficult waste stream.

The downstream effluent showed significantly reduced levels of colour and total organic carbon, marking a step forward in environmental remediation. It’s a powerful example of the circular economy in action, turning pollutants into products.

Importantly, this method does not require vast land areas or extensive infrastructure. That’s in contrast to traditional potash recovery methods, which often involve evaporating seawater or mining underground deposits. Both are land- and energy-intensive, and increasingly vulnerable to climate volatility.

A global need for local solutions

The implications of this study go far beyond India. Countries across the Global South face twin challenges: rising fertiliser costs and growing industrial pollution. Technologies like this offer a localised, decentralised alternative that taps into waste streams already available at the source.

For example, sugar-producing nations in Africa and Latin America generate similar types of distillery waste. Adopting this technology could reduce their dependence on imported fertilisers, cut pollution, and improve food security in a single move.

Moreover, potassium-rich effluents are not unique to distilleries. Similar waste streams are found in agro-industrial operations, fertiliser plants, and even food processing units. With further research and investment, this model could be adapted and scaled across industries.

Not just science, but policy and practice

But science alone won’t solve the problem. Scaling this innovation will require alignment with environmental policies, subsidies for cleaner technologies, and perhaps even mandates for potassium recovery in industries.

India’s current focus on waste-to-energy and circular economy solutions under schemes like the Swachh Bharat Mission could provide fertile ground for pilot projects and industry collaborations.

Fertilising the future

In a warming world with shrinking resources, innovations like this may define the future of farming. Instead of relying on fragile supply chains, we can start mining our own waste. If scaled properly, this could become a cornerstone of regenerative agriculture, where waste is not just managed but transformed.

The numbers are promising: 70 percent recovery of potassium, 77 percent conversion into potassium nitrate, and 80 percent regeneration of tartaric acid. This is not an incremental improvement; it’s a leap forward.

Yet, as with many scientific advances, the road from lab to field is long. Cost-benefit analyses, real-world pilot testing, and industrial buy-in will be essential to making this more than a clever idea.

Can our waste really grow our food?

This study from IIT Bombay raises a tantalising possibility: could the pollutants of today become the fertilisers of tomorrow?

As the climate crisis accelerates and global inequalities deepen, the race for sustainable fertiliser sources is not just a technical challenge, but a moral imperative. Circular, local, and environmentally conscious solutions like these might be our best bet for resilient food systems.

What other treasures are hiding in our trash?

References

Khatri, I. and Garg, A., 2022. Potash recovery from synthetic potassium rich wastewater and biomethanated distillery effluent using tartaric acid as a recyclable precipitant. Environmental Technology & Innovation, 28, p.102841. https://doi.org/10.1016/j.eti.2022.102841