It starts with a smell. A pungent, eye-watering stench rising from blackened waterways near distilleries. For locals in Maharashtra and across India, this is the scent of industrial alcohol production. What most don’t see is the silent ecological damage that follows. But in a lab at IIT Bombay, researchers may have found a surprising solution: copper. More specifically, a copper-based heterogeneous catalyst that doesn’t just clean this wastewater but also transforms it into a source of renewable energy.

As India grapples with an ongoing pollution crisis, research like this could shift the tide. Industrial waste, particularly from alcohol distilleries, is one of the country’s most persistent water pollutants. The good news? A breakthrough study led by Dr Inderjeet Khatri is turning a notorious pollutant into a promise for the future.

The murky truth behind your morning toast

The sugar industry fuels more than sweet cravings. It also powers the alcohol sector through the fermentation of molasses, a dark syrupy by-product of sugar refining. What’s left after distillation is even darker: spent wash. This thick, brown liquid is acidic, foul-smelling and packed with organic matter that chokes rivers and kills aquatic life.

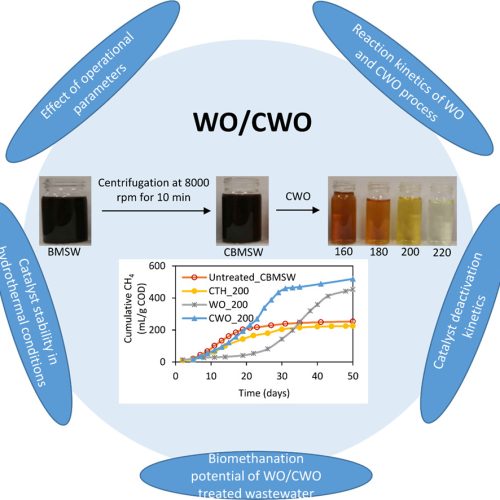

Despite efforts to treat it, even after biomethanation (a common anaerobic digestion technique), the resulting stream, called biomethanated spent wash (BMSW), remains a major challenge. It retains high chemical oxygen demand (COD), persistent colour, and harmful compounds like melanoidins. Conventional methods barely scratch the surface, leaving behind a wastewater cocktail that is resistant to degradation.

Enter catalytic wet oxidation: A chemical cleanup with a twist

Dr Khatri investigated a chemical-free treatment process called catalytic wet oxidation (CWO), where heat, pressure, oxygen, and a heterogeneous catalyst work together to break down pollutants. Their choice of catalyst? Recyclable activated carbon supported with copper (5% Cu/AC). It sounds modest, but its impact was substantial.

At 220 degrees Celsius and under oxygen-rich conditions, their trials showed a 72% reduction in COD and an astonishing 97% removal of colour. The treated water also became far more biodegradable, making it suitable for further anaerobic digestion.

What surprised us was not just the degree of treatment, but the energy potential of the by-products. The remaining compounds could be converted into methane-rich biogas.

-Dr. Inderjeet Khatri

From sludge to spark: Creating energy from waste

After the CWO treatment, the researchers subjected the water to a biochemical methane potential (BMP) test. The results were remarkable. Compared to untreated BMSW, the CWO-treated samples generated nearly 1.7 times more biogas. Not only was more methane produced, but the digestion process became faster and cleaner.

Methane, a primary component of natural gas, can power homes, fuel vehicles or generate electricity. In a country struggling with waste management and energy security, this two-fold benefit, pollution control and energy generation, offers compelling potential.

A chemical balancing act

The core process involves a dance of oxygen, free radicals and copper ions. The heterogeneouscatalyst helps convert organic molecules like acetic acid and melanoidins into smaller, biodegradable compounds. This involves a series of oxidation reactions where heat and oxygen are key, but the copper catalyst accelerates and stabilises the entire process.

One of the challenges, however, lies in the catalyst’s longevity. Over time, its effectiveness decreases due to fouling and leaching. The IIT Bombay team observed that the catalyst could be reused effectively for two cycles after regeneration via thermal calcination, but beyond that, its performance drops.

To counter this, researchers suggest exploring more robust catalyst supports like zirconium dioxide or mixed-metal systems in future studies. Nevertheless, their findings already indicate that copper-based CWO is a serious contender for industrial-scale adoption.

Wastewater, climate, and energy security

Why does this matter now? Because India is facing multiple converging crises. Water pollution is at critical levels, especially in river basins near industrial zones. Meanwhile, the push for renewable energy is growing as the country commits to ambitious climate goals.

The new study ties directly into these national priorities. It proposes a circular economy approach, where waste isn’t just a by-product but a resource. Cleaner rivers, lower greenhouse gas emissions, and decentralised energy production, stem from the same solution.

Globally too, the science community is looking beyond conventional wastewater treatment. The United Nations has declared wastewater as the next frontier for sustainable development. Research like this could put India at the forefront of that movement.

Challenges on the horizon

While the results are promising, scaling up is not without hurdles. The high temperatures and pressures required for CWO mean that distilleries would need significant infrastructure investments. Catalyst degradation also needs to be addressed for long-term use.

There are regulatory gaps as well. Waste-to-energy strategies involving complex chemical processes fall between environmental and industrial frameworks in India. Clearer policies and incentives will be needed for this solution to take off.

Still, the cost of inaction is higher. According to a recent report by the Central Pollution Control Board, nearly 85% of distilleries in India fail to meet the discharge standards for BMSW. Technologies like CWO could be the missing link.

The bigger picture

This research doesn’t just offer a better way to treat waste. It reimagines waste itself. Instead of a disposal problem, spent wash becomes a feedstock for clean energy. It encourages industries to think not just about what they produce, but what they leave behind. And in a world inching closer to resource exhaustion and climate tipping points, such rethinking is essential.

The IIT Bombay study could pave the way for decentralised wastewater-to-energy hubs, especially in rural and semi-urban areas where distilleries are common. Pilot-scale demonstrations and public-private partnerships may help validate the economic feasibility.

Researchers are also keen on exploring how this technique could be adapted for other industrial effluents, like dye wastewater or pharmaceutical residues. The versatility of CWO opens many doors.

A new kind of alchemy?

Turning wine into water might be the stuff of miracles. But turning liquor waste into energy? That’s modern science. Copper, often associated with old coins and electrical wiring, could now become a symbol of environmental renewal.

For the billions living in the shadow of polluted waterways, such breakthroughs offer more than scientific achievement. They offer hope.

As India builds its future on the pillars of sustainability, innovation and resilience, it must rethink its relationship with waste. Studies like this remind us that even the most toxic leftovers can become tools of transformation.

So, the next time you hear about cleaner energy or pollution-free rivers, ask yourself: could it start with a catalyst? And maybe, just maybe, a touch of copper?

Reference

Khatri, I. and Garg, A., 2021. Use of heterogeneous activated carbon supported copper catalyst for catalytic wet oxidation of biomethanated spent wash: Reaction kinetics, catalyst stability, catalyst deactivation kinetics and biochemical methane potential. Journal of Water Process Engineering, 44, p.102387. https://doi.org/10.1016/j.jwpe.2021.102387