Clean drinking water remains one of the greatest public health challenges of the twenty-first century. According to the World Health Organization, contaminated water is responsible for more than 500,000 diarrhoeal deaths every year, most of them among children in low-income regions. Modern water treatment facilities in wealthy nations use sophisticated chemical and membrane technologies, but for rural villages in developing countries, such systems are either too expensive or logistically impossible to install.

A recent study by Antoni Sánchez-Ferrer and Jenifer Guerrero Parra at the Technical University of Munich, published in Wood Science and Technology, suggests that a simple yet powerful solution may be found in nature itself: wood. Their research systematically examined different wood species and their ability to act as natural water filters, with results that could reshape the future of household water treatment.

By testing species such as European beech (Fagus sylvatica) and silver fir (Abies alba), the researchers discovered that wood filters can remove more than 99 per cent of nanoparticle contaminants, including those similar in size to harmful bacteria and protozoa. Beyond microbes, wood also shows the capacity to trap microplastics and nanoplastics, contaminants increasingly recognised as environmental threats. The study positions wood not only as a sustainable and low-cost option but also as a surprisingly effective scientific innovation rooted in natural design.

The global water crisis

Although water covers 70 per cent of Earth’s surface, only a tiny fraction is safe for direct human consumption. Of the 2.5 per cent that is freshwater, just 0.26 per cent is readily available for people. For the 2 billion individuals worldwide without access to safe drinking water, this shortage translates into malnutrition, outbreaks of waterborne disease, and preventable deaths.

Centralised water treatment systems in developed countries rely on processes such as chlorination, filtration, and reverse osmosis. These systems require vast infrastructure, consistent energy supplies, and professional monitoring. For small rural communities, particularly in developing regions, such demands are out of reach.

This is why point-of-use water treatment solutions are considered essential. Low-cost methods like solar disinfection, biosand filtration, and ceramic filters have gained attention, but each carries limitations. Solar pasteurisation depends heavily on the weather. Ceramic filters are fragile and energy-intensive to produce. Biosand filters are effective only against certain microbes and require bulky installations. In this landscape, the appeal of a cheap, locally available, and robust material like wood becomes obvious.

Wood as nature’s sieve

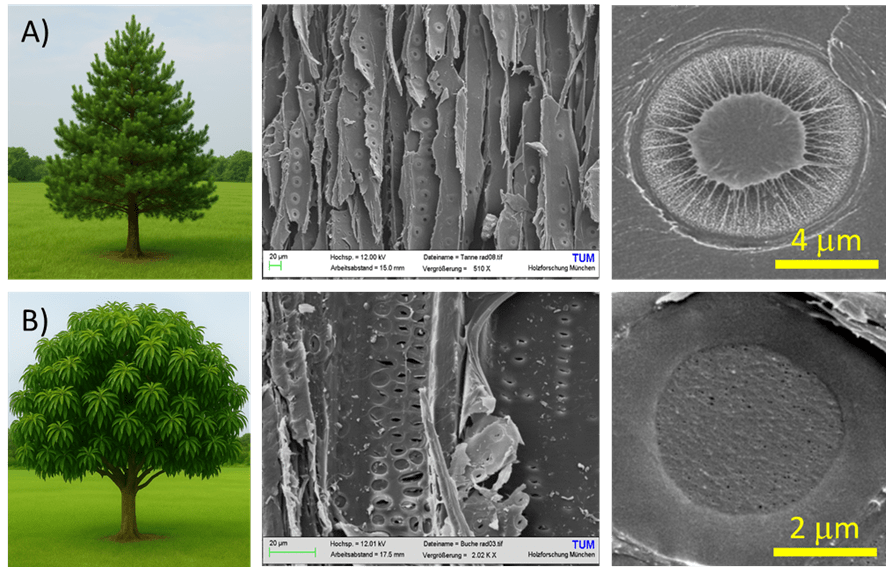

Wood is more than a structural material for construction. Its anatomy includes an intricate network of pores, such as tracheids in coniferous trees, and fibres and vessels in flowering trees, including rays and pits (Figure 1), originally designed to transport water and nutrients in trees, with the latter being primarily responsible for removing nanoparticles. These microscopic pathways provide a natural sieve that can retain particulate matter.

The Munich researchers cut sections of yellow poplar (Liriodendron tulipifera), European beech (Fagus sylvatica), Douglas fir (Pseudotsuga menziesii), and silver fir (Abies alba) into thin discs and tested them as filtration membranes. The direction of the cut proved critical. In radial and tangential orientations, wood filters showed far greater efficiency than in the longitudinal direction. This difference is linked to how water travels through pits and rays in the wood structure, forcing contaminants into longer residence times and tighter passages.

Under laboratory tests, beech and silver fir achieved over 99 per cent removal of iron oxide nanoparticles in the 500-nanometre range, effectively simulating the size of many bacteria. This performance compares favourably with engineered membranes, highlighting wood’s potential as a naturally optimised filter.

Figure 1: A) Intertracheary pit membranes in coniferous trees (gymnosperms), and B) intervessel pit membranes in flowering trees (angiosperms)

Beyond microbes: Targeting plastics and chemicals

The study also explored whether wood could filter contaminants beyond bacteria. Nanoparticles of silica, guar gum, and nanocellulose were used as tracers to mimic diverse pollutants. Results indicated that wood filters could exclude particles in the critical 160 to 490 nanometre range, which includes many microplastics and nanoplastics.

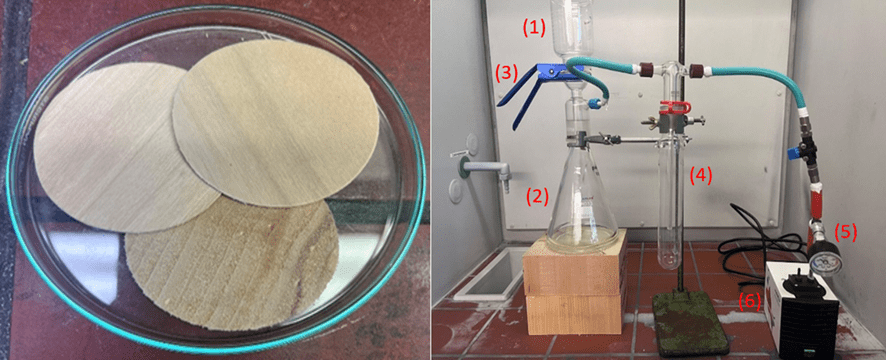

These findings are especially relevant given the global alarm over plastic pollution. Microplastics have been detected in drinking water supplies, food chains, and even human bloodstreams. A low-cost natural filter capable of capturing such particles could become an invaluable public health tool (Figure 2).

The researchers further tested small organic molecules such as methylene blue and azobenzene. These dyes are similar in scale to industrial contaminants and pharmaceuticals that often seep into water sources. While the removal rates were lower than for nanoparticles, wood still demonstrated measurable adsorption and diffusion of such molecules, aided by electrostatic interactions with cellulose, hemicellulose, and lignin in the wood cell wall.

Figure 2: Left: Wood filtration disks (50 mm diameter and 1 mm thickness). Right: Setup for the filtration experiments: graduated funnel (1), filter flask (2), aluminium clamp (3), water trap (4), pressure gauge (5), and vacuum membrane pump (6).

Comparing wood with existing household technologies

To assess practical applications, Sánchez-Ferrer and Guerrero Parra compared wood with other point-of-use technologies. Chlorination, while highly effective, requires a constant supply of chemicals and infrastructure. Solar disinfection is inexpensive but weather-dependent and less efficient against protozoa. Biosand and ceramic filters provide reasonable protection but involve maintenance and fragility issues. Biochar offers good adsorption but requires high energy for production and frequent replacement.

Wood, in contrast, is locally available, requires minimal processing, and offers strong filtration results at a competitive cost. The researchers estimate that a wood filter could cost between 0.28 and 0.34 US dollars per month for a family of five, based on European log prices. This places wood filtration well within the affordability range for low-income households, rivaling or undercutting other established methods.

Moreover, unlike synthetic membranes that often must be imported, wood can be sourced from local forests. This not only reduces supply chain dependency but also creates opportunities for local economies to participate in filter production and distribution.

Pores and particles

Understanding why wood works as a filter requires delving into its microstructure. Beech wood, for example, contains pits with diameters between 2 and 5 micrometres, functioning as natural bottlenecks. When water flows through these narrow passages, larger nanoparticles and microbes are trapped.

The researchers observed that in the radial and tangential directions, filtration efficiency soared because particles encountered longer and more complex pathways. Flow rates in these directions were slower than in the longitudinal cut, but this slower movement gave contaminants less chance to slip through.

This balance of geometry, flow, and particle size exclusion mirrors engineered filtration systems. Yet in this case, the design was not created in a laboratory but by millions of years of plant evolution. The study highlights how scientific methods like dynamic light scattering (DLS) and scanning electron microscopy (SEM) can reveal and quantify these natural mechanisms.

Practical testing and future optimisation

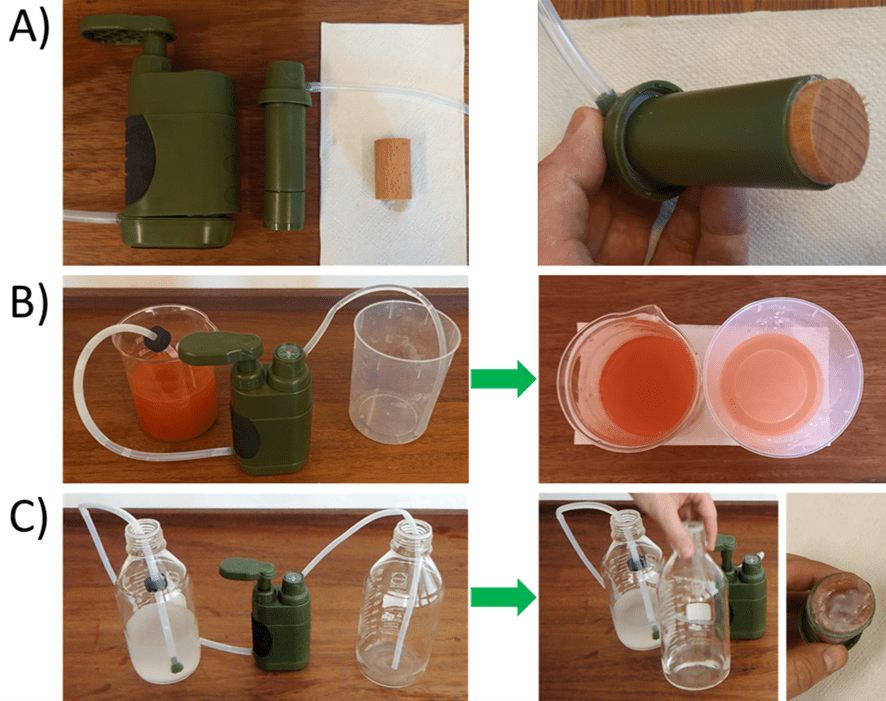

The Wood Materials Science group led by Sánchez-Ferrer did not stop at theoretical insights. They built prototype filters by inserting beech wood cylinders into a commercial water pump system. These low-tech devices successfully reduced nanoparticle concentrations from over 100 parts per million to less than 10 parts per million. Videos of the filtration process demonstrated the feasibility of portable, manual, and affordable systems.

Optimisation remains a priority. The study found that thicker wood filters could achieve near-total removal of nanoparticles at higher flow rates. For example, increasing the thickness to a few millimetres allowed for 99 per cent removal of 500-nanometre iron oxide particles. Sánchez-Ferrer’s team has also explored chemical modifications of the wood lumina to fine-tune filtration for specific contaminants, i.e., negatively charged molecules and ions. Their work was published in the Journal of Bioresources and Bioproducts. They are currently working on the removal of positively charged molecules, cations and heavy metals.

The researchers envision wood filters serving as pretreatment steps before ultrafiltration or reverse osmosis, thereby reducing fouling and extending the lifespan of expensive synthetic membranes. This layered approach could combine affordability with advanced purification when needed.

Figure 3: Details of a manual water filtration system using a beech cylinder of 4.5 cm in length and 2.5 cm in diameter. A) Filtration system and beech filter. B) Filtration of 0.01% iron oxide nanoparticles. C) Filtration of 0.1% silica microparticles.

Sustainability and social impact

The appeal of wood filtration extends beyond science. As a renewable resource, wood offers a sustainable alternative to synthetic polymers or fragile ceramics. If produced locally, wood filters could reduce dependency on imports and stimulate rural economies.

For communities struggling with unsafe water, the ability to craft filters from nearby forests represents more than convenience. It embodies empowerment and resilience. The study notes that while clogging from suspended solids remains a challenge, combining wood with coarse pre-filtration methods like sand could provide a comprehensive solution.

At a global level, wood filtration could align with Sustainable Development Goal 6: ensuring availability and sustainable management of water and sanitation for all. By making clean water more accessible, it could also improve health, education, and economic opportunities in underserved regions.

Wood is a readily available and affordable natural material that can purify water when used as a filter, removing protozoa, bacteria, micro- and nanoplastics, meeting a family’s water needs at a very low cost.

–Antoni Sánchez-Ferrer

The road ahead

Although promising, wood filters are not a silver bullet. They will not replace industrial-scale treatment plants or advanced desalination technologies. However, they could provide an essential bridge for communities without access to such infrastructure.

Future studies will likely focus on tailoring wood filters for targeted contaminants, exploring functionalisation with polymers or nanoparticles to improve selectivity. Research may also examine durability, regeneration techniques, and long-term safety. Importantly, partnerships between scientists, policymakers, and NGOs will be needed to translate laboratory results into real-world impact.

Sánchez-Ferrer and Guerrero Parra’s work underscores how blending fundamental Wood Science and Materials Science with global health needs can produce meaningful innovation. It also reminds us that sometimes the answers to modern challenges lie hidden in ancient natural materials.

The research invites a broader reflection: when searching for solutions to global challenges, perhaps we should look not only to advanced laboratories but also to the forests that have sustained life for millennia.

Reference

Sánchez-Ferrer, A., & Guerrero Parra, J. (2025). Exploring wood as a sustainable solution for water filtration: nanoparticle removal, size exclusion and molecular adsorption. Wood Science and Technology, 59(42). https://doi.org/10.1007/s00226-025-01645-7

Ahmed, M.J., Wu, B., & Sánchez-Ferrer, A. (2025). Anion Exchangers Prepared from Graft Polymerisation of Microfibrillated Cellulose Using the Reactive Ionic Liquid. Journal of Bioresources and Bioproducts, 10(3). https://doi.org/10.1016/j.jobab.2025.04.001