As the world grapples with a phosphorus shortage threatening agricultural productivity and global food security, researchers at Nanyang Technological University (NTU) in Singapore are pioneering an ingenious approach to tackle two persistent environmental challenges at once: waste disposal and resource scarcity. Phosphorus, a critical nutrient essential for plant growth, is increasingly scarce. Yet every day, tonnes of phosphorus-rich sewage sludge and its ash are dumped in landfills worldwide. Could rethinking how we treat waste unlock a sustainable future?

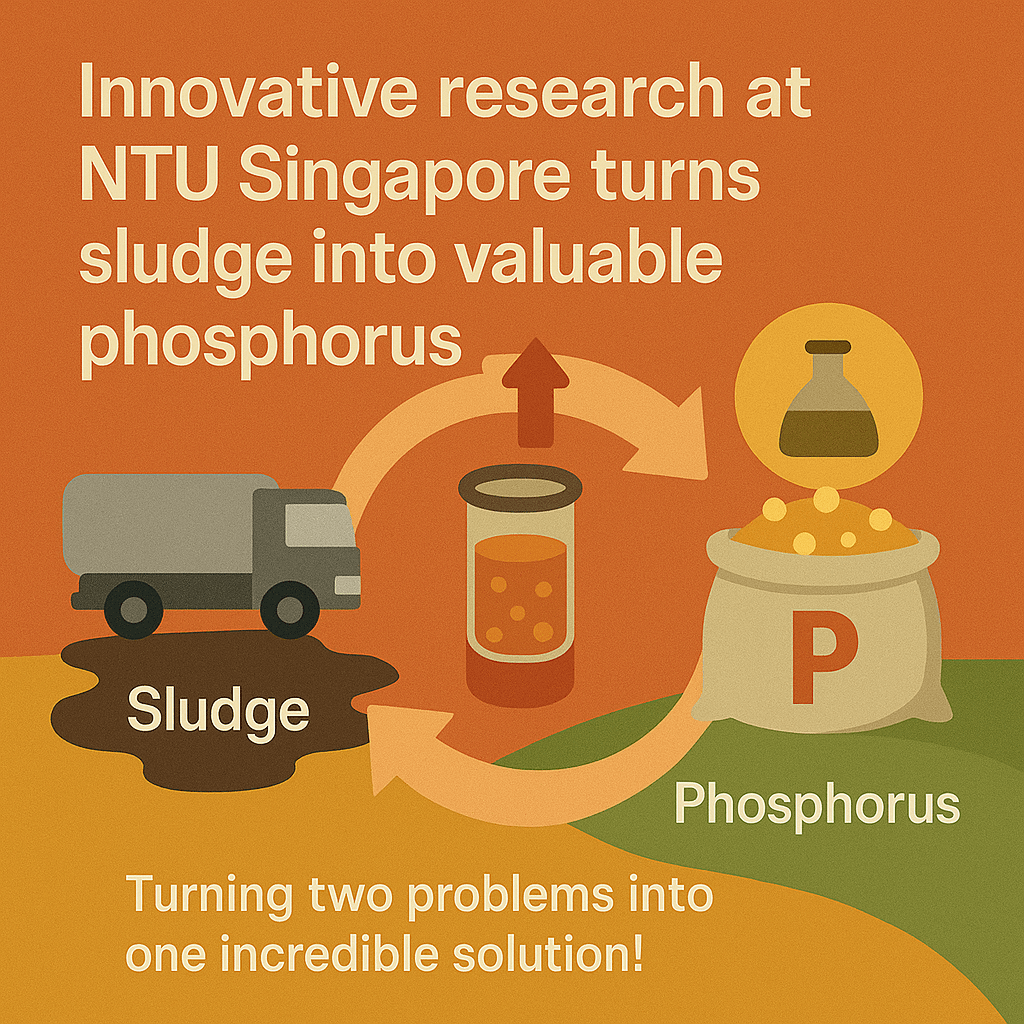

In recent research published in the Chemical Engineering Journal, first author Satya Brat Tiwari and colleagues introduced a novel, and potentially cost-effective method to extract phosphorus from sewage sludge using alum sludge, a by-product of water treatment plants. Their work promises significant advances in waste management and sustainable agriculture, converting previously neglected materials into valuable resources.

From waste dilemma to sustainable solution

Sewage sludge, the semi-solid by-product of wastewater treatment, is an underutilised resource loaded with phosphorus. Typically, sewage sludge disposal methods include incineration or landfilling, which contribute significantly to greenhouse gas emissions and environmental pollution. Alum sludge, similarly discarded, is the residue left behind after alum (aluminium sulphate) is used in drinking water purification. Both these waste materials, conventionally treated as environmental burdens, hold untapped potential.

Tiwari’s team at NTU realised that combining these two waste streams could achieve multiple environmental benefits. Their approach involves acid pretreatment of sewage sludge mixed with alum sludge, followed by a pyrolysis process, a chemical decomposition achieved by heating in an oxygen-free environment. This transforms sludge into a stable material known as “char”, rich in phosphorus but significantly lower in harmful heavy metals.

Making phosphorus recovery cleaner and safer

The research, highlighted in Chemical Engineering Journal, indicates impressive results. By pyrolysing the amended sewage sludge at relatively low temperatures (around 400°C), the team successfully recovered up to 88% of the phosphorus present using alkaline extraction, dramatically outperforming conventional methods. This innovative method also significantly reduced the heavy metal content typically associated with phosphorus recovery processes, making the recovered phosphorus safer for subsequent use.

This process not only increases phosphorus recovery efficiency but also effectively tackles the challenge of heavy metal contamination, a significant obstacle in reusing sewage sludge as phosphorus source.

-Satya Brat Tiwari

At higher pyrolysis temperatures, phosphorus tends to bind strongly with carbon, reducing its extractability. Thus, lower temperatures are ideal, making the process less energy-intensive and more sustainable.

Breaking down the science: Phosphorus speciation

To understand why this process is so effective, it’s essential to delve into “phosphorus speciation”, how phosphorus exists chemically within sludge. Typically, phosphorus in sewage sludge is present as diverse forms that’s hard to dissolve in water and extract efficiently. However, when sewage sludge is mixed with alum sludge and treated with acid, the apatite phosphate converts into non-apatite inorganic phosphate (NAIP). Since NAIP dissolves in an alkali while heavy metals do not, alkaline extraction of amended sewage sludge char produces phosphorus rich but heavy metal deficient alkaline extract.

“Our approach converts difficult-to-extract phosphorus into a form that readily dissolves in alkaline solutions,” explains Tiwari. This breakthrough effectively bypasses the limitations of traditional phosphorus extraction methods, resulting in higher yields with fewer impurities.

An environmental and economic game changer

Globally, landfills are overflowing, and the environmental impacts of waste disposal are escalating. Meanwhile, agriculture faces a looming crisis with phosphorus, a finite, non-renewable resource. This innovative phosphorus recovery method not only alleviates these issues but also aligns perfectly with global sustainability goals and circular economy principles, where waste materials become resource inputs for new processes.

Economically, this approach is equally promising. Alum sludge is freely available in large quantities worldwide. Integrating it into existing waste management frameworks reduces the costs associated with chemical additives typically used in phosphorus extraction. This makes the method not only environmentally friendly but also economically attractive.

Linking waste management to global climate action

The NTU study is particularly timely, given the increasing global awareness and urgency around climate change mitigation strategies. The Intergovernmental Panel on Climate Change (IPCC) continues to highlight sustainable waste management and resource recovery as vital components in reducing greenhouse gas emissions and environmental degradation.

As nations worldwide grapple with commitments to lower emissions and reduce environmental footprints, innovative waste-to-resource solutions like this could become pivotal. Such approaches address multiple environmental concerns simultaneously, offering practical, scalable solutions that can be adopted globally.

Unlocking broader environmental benefits

Beyond phosphorus recovery, the alum-sludge amended char produced in this process could potentially be used for other environmental applications. Due to its improved porosity and reduced toxicity, this char shows promise as an adsorbent for pollutant removal in wastewater treatment. Further research and technological refinements might soon expand its use, presenting new opportunities in waste management and environmental remediation.

Moreover, the recovery process significantly reduces heavy metal presence in the final phosphorus product, addressing one of the critical barriers to using recycled phosphorus in agriculture. This could increase farmers’ confidence in recycled fertilisers, driving greater adoption and helping create a more sustainable agricultural sector.

Challenges ahead and future directions

While the results from NTU’s study are promising, scaling the technology to commercial levels presents its own set of challenges. Initial investments, infrastructure upgrades, and integration with current wastewater treatment facilities require careful economic and feasibility studies.

Future research directions include assessing long-term environmental impacts, detailed cost-benefit analyses, and exploring ways to enhance process efficiency further. Researchers are also considering the potential recovery of aluminium as a valuable co-product, further enhancing the economic feasibility and attractiveness of this method.

A global call to action

The phosphorus recovery innovation from NTU is not just a scientific breakthrough but a timely reminder of our urgent need to rethink waste management globally. Policymakers, industry leaders, and communities must now seriously consider adopting and supporting innovative solutions like this to drive sustainable change.

Governments could incentivise recycling and phosphorus recovery methods, establishing clear guidelines and supportive frameworks that facilitate the transition from traditional waste disposal to resource recovery. Industries, particularly wastewater treatment and agriculture sectors, must also proactively engage with researchers to explore implementing such innovations practically.

Is the future of sustainability hiding in our waste?

With this compelling new approach to phosphorus recovery, the question now shifts to global society: Are we ready to transform our waste management practices and embrace innovations that deliver substantial environmental and economic benefits?

Our response to this question could determine not only how we manage waste today but also the environmental legacy we leave behind for future generations.

References

Tiwari, S. B., Chin, S. Y., Veksha, A., Chan, W. P., Fei, X., Lisak, G., … & Lim, T. T. (2024). Synergistic application of alum sludge and sequential extraction for phosphorus recovery from sewage sludge char. Chemical Engineering Journal, 481, 148574. https://doi.org/10.1016/j.cej.2024.148574

Tiwari, S. B., Hooper, T. J., Veksha, A., Chan, W. P., Fei, X., Liu, W., … & Lim, T. T. (2023). Sequential wet extraction of phosphorus from sewage sludge using alum sludge: reassessing the aluminium-phosphorus speciation using experimental and simulation approach. Chemical Engineering Journal, 459, 141569. https://doi.org/10.1016/j.cej.2023.141569